Fuel cells pave the way for cars of the future

After the electric car and the plug-in hybrid come the fuel cells, according to Patric Jannasch, Professor of Polymer Technology at Lund University. The technology, which was hyped in the late 1990s but has since been put on a backburner, is now close to commercialisation.

“Internationally, the car industry is investing heavily in fuel cells. This would not have happened if they didn’t believe in the technology”, says Patric Jannasch, who has taken part in a number of major EU projects on fuel cells.

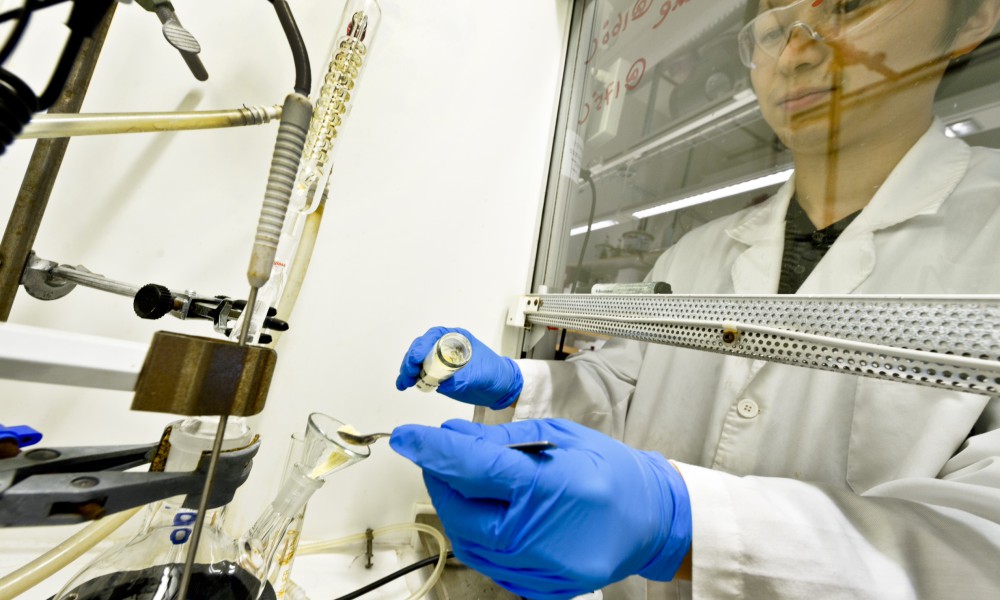

Patric Jannasch’s doctoral student Shogo Takamuku worked as a fuel cell developer at Nissan in Japan for several years. He came to Lund nearly four years ago to benefit from Kemicentrum’s successful research on polymer membranes, a kind of plastic film that plays a key role in fuel cells. He describes the fuel cell as a further development of the technology in the electric car.

“With the electric car, car manufacturers learn to deal with electricity. It then becomes easier to take the next step to fuel cell technology”, says Shogo Takamuku.

A fuel cell car also runs on electric batteries. However, instead of energy coming from a rechargeable battery, the car is filled up with hydrogen gas. The exhaust pipe releases – water! The hydrogen gas first enters the fuel cell, which looks like a striped metal box the size of a suitcase. There the electrons are separated out and sent on to power the motor. The protons are dealt with by the polymer membrane. The plastic film, catalyst layer and gas distribution plates give the fuel cell its layered appearance.

Shogo Takamuku and Patric Jannasch have now found a new way to manufacture cheaper, more efficient and more environmentally friendly plastic film. This is welcome news, as production costs have long been the greatest obstacle to fuel cell technology.

“The polymer membrane can also be applied to filter sand from sea water.”

With the Lund researchers’ invention, the membrane’s raw material can be replaced with a cheaper alternative and the number of steps in the production process can be reduced from 12 to 4. In addition, the plastic film can withstand higher temperatures, which makes the entire fuel cell system more efficient and cheaper.

What researchers have come up with is the molecular design of a self-assembling polymer that makes the plastic more robust. The membrane can also be applied to other uses, such as to filter sand from sea water. An international patent is pending for the special molecular structure, and it is described in the thesis that Shogo Takamuku presented recently.

“At the moment we are in discussions with an international membrane company that wants to buy our invention”, says Patric Jannasch, explaining that car manufacturers do not produce the plastic film themselves, but rather purchase it from suppliers.

He thinks that Sweden should draw up a national plan for the development of the technology and invest in it.

“Important components in fuel cells are made of metal, and we have vast metal resources. In a smart electricity grid of the future, fuel cells can be run in reverse to convert excess energy from wind power, for example, into hydrogen gas that can be used when required”, he says.

On the other hand, he doesn’t believe that Sweden will necessarily be the country where fuel cell cars will principally be used.

“We have large amounts of forest, so we may be able to run cars on biogas or biodiesel. However, in Japan, Germany and other countries with less access to biomass, fuel cell technology is needed.”

Text: Kristina Lindgärde

Published: 2013