Driven by a machine

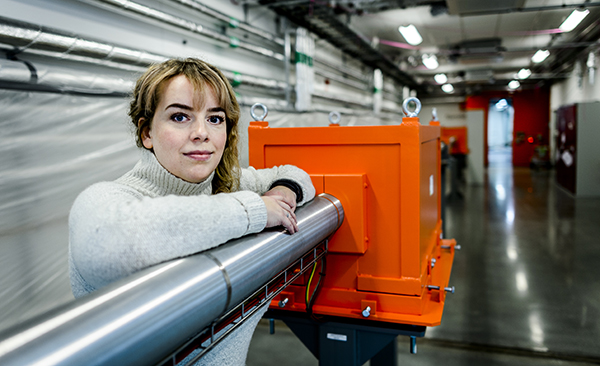

As a child, Sara Thorin dreamed of becoming a physicist. As a project leader for one of MAX IV Laboratory’s most central components – the linear accelerator – she has a great responsibility for ensuring the world’s best synchrotron radiation facility delivers light of exactly the right quality to reveal the secrets of a hitherto unknown microcosm.

Think of something really fast!

A racing car?

A Formula One car at top speed moves at about 90 metres a second. That is very fast. In the same time the electrons fired off by Sara Thorin and her colleagues travel a distance that is 3.3 million times further. In round numbers that is 570,000 circuits of the MAX IV Laboratory’s large accelerator ring – the 3GeV ring* – with a circumference of 528 metres. That’s every second – at a rate not far short of the speed of light.

THIS MIND- BOOGLING SPEED is reached in the first five metres of a 300-metre-long linear accelerator (LINAC), in which the electrons are accelerated with extreme precision and then charged with large amounts of energy before being injected into one of MAX IV Laboratory’s three test facilities – the 3 GeV ring, the smaller 1.5 GeV ring and the Short Pulse Facility (SPF) – which all have different functions.

“ The difference between the large and the small ring is mainly the wavelengths of the light that are produced”, explains Sara Thorin. “In the large ring, the electron beam has higher energy and produces light with a shorter wavelength, whereas the small ring produces longer wavelengths. In this way we can create the best conditions for different types of studies, such as investigating materials where the components are at various distances from each other.”

“MAX Lab has been my dream workplace for a long time”

At present the LINAC routinely supplies electrons to the 3 GeV ring and 1.5 GeV ring. Current work is focused on what is perhaps the LINAC’s most demanding task – to achieve the extremely short light pulses required in the MAX IV’s Short Pulse Facility.

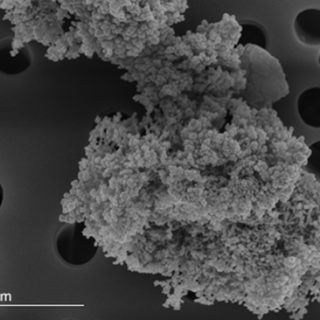

“Using the SPF, researchers will be able to study very fast processes that require a high resolution. This could, for example, concern chemical reactions that take place within extremely short time spans. Today we can create stable pulses in under a picosecond – one trillionth of a second – but with further fine-tuning we will get down to some tenths of a femtosecond, i.e. thousandths of a picosecond. It can be compared to a camera that has an extremely short shutter speed. With the SPF we will be able to take sharp images of things that we could only imagine before. It will give us a lot of new, exciting insights.

VISITORS TO MAX IV LABORATORY cannot help but be fascinated by constant reminders of the contrasts and range between large and small. On the one hand there are the enormous speeds and energies, and on the other the nanometre precision required to direct the electron beam in exactly the right way. On the one hand there are the enormous buildings with their metre-thick concrete walls, robust steel structures and heavy-duty electric cables, and on the other the invisible, tiny molecular structures whose secrets have driven the construction of MAX IV Laboratory – the search for a better understanding of the world around us. Perhaps it was also this that made Sara Thorin choose physics.

Her studies at LTH for a Master of Science in Engineering degree, specialising in engineering physics, were completed very quickly. In 2004, after her degree project in atomic physics, Sara Thorin was granted a doctoral studentship at MAX Lab, a workplace she describes as a haven for physicists and engineers.

“MAX Lab has been my dream workplace for a long time. It was, and is, a fantastic environment with people inspired by a shared mission – to get the electrons to follow predetermined paths using increasingly large and ever more awesome machines and energies.”

Sara Thorin and her collegue Erik Manten in one of the control rooms at MAX IV

SARA THORIN`S RESEARCH on free-electron lasers meant that even in her time as a doctoral student she was making calculations about the short pulses that are to be delivered by the LINAC. This work resulted in her eventually, at just 30 years of age, getting the job of leading one of the truly central projects within MAX IV – the construction of the linear accelerator – a billion crown project in a project worth billions.

“In fact, I have been working on the LINAC in MAX IV since 2006, starting just after MAX III opened. In the beginning it was a project on the drawing board, with numerous major and minor problems that had to be solved in theory. Gradually, however, the feeling increased that it was becoming more and more real, and two and half years ago it was time to start the installation of the LINAC.”

Sara Thorin was one of the first to move to the building site in northeast Lund, which at that time consisted of windswept muddy fields and a few portacabins. The organisation gradually grew as more and more qualified people were employed. As project leader, Sara Thorin had responsibility for coordinating some 15 different working groups, each with demarcated tasks, and there was a considerable need for smooth communication in order for everything to work.

TODAY, the building site looks a lot different. The huge, futuristic-inspired buildings are in place, with proportions that are hard to take in. The muddy fields have been transformed into a rolling landscape with flourishing vegetation and twinkling watercourses. However, the external calm is deceptive, as these buildings are seething with carefully controlled activities. Each beamline – where the testing is done – requires an installation consisting of several tons of equipment in stainless steel, kilometres of electric cables and numerous fast computers and hyper-sensitive measurement instruments. At the moment there is still quite a lot of space between the large ring and the outer wall, but space will be constricted when everything is in place.

MAX IV Laboratory will soon be teeming with life, but the office building’s large canteen is quite empty for now. Today’s small group of visitors has a magnificent view of Lund’s new mega- investment, ESS, which has already come a long way. In combination with MAX IV, it will make Lund perhaps the world’s most attractive materials research site for a long time to come. In a completely different part of the building is Sara Thorin’s office, which has a view of the Ideon area. However, this is not where she spends her working days. Highly focused work is going on in the control room down the corridor. Just inside the door is a panel with emergency stop switches, in case something should go wrong. Along the walls are tables supporting large screens in groups of four that show various processes and sequences in the large facility. One screen shows a cross section of the diamond-shaped electron beam. It is almost perfect. About ten operators and accelerator physicists are engrossed in calm discussions. Now and then they glide between screens on the castors of their swivel chairs. They meet in a group to discuss, interpret and perhaps correct something that has shown up on someone’s screen. They are working on the operation of the LINAC and towards the start up of the large storage ring. Now it is for real. The facility will soon be in full operation, with tests 24 hours a day. Sara Thorin looks at home in the environment. It is clear that she has things under control. It is time for the inevitable question. She is one of very few women in the accelerator project – what is it like to have managerial responsibility in this totally male-dominated world?

“It’s true that the percentage of women is very low, both here at MAX IV and within physics in general, but happily that is starting to change. For one thing, there are many talented female doctoral students on the way up. For me, there have been both advantages and disadvantages. At times I have had to fight a little harder to be taken seriously, but it also makes it easier to be remembered, which is no bad thing.”

ON 21 OF JUNE, the day of the summer solstice, the light was released for the first time for real, which was clearly symbolic. Sara Thorin is proud to play a central role in a project that will enable new and exciting discoveries. However, her own self-motivation lies with the machine itself and the task of delivering the exact right light, the right concentration, the right wavelength and exact pulsation. This work does not end in connection with MAX IV being operational, however.

“I will be going into more of a maintenance phase, but there will still be a great amount of development work left to do. This will concern things like customising the pulses to provide the best results in different kinds of investigations. It is work carried out in close cooperation with researchers from a number of different fields and it will be very exciting. I also hope to spend a little more time on receiving study visits. Telling the public about what we do here is an important task that shouldn’t be forgotten. It is after all the public that pays for a large part of our activities and there are a lot of exciting things to talk about.”

JUST LIKE THE PREVIOUS generations of MAX Lab, MAX IV Laboratory is prepared for the next phase in the development of synchrotron light. However, this time it will not be a matter of building a new giant facility, but of taking the facility’s existing technology one step further. The next objective is a coherent light, a super-intensive X-ray with wavelengths in perfect phase and with no spread – a light that allows you to see interference patterns in the investigated material and arrive at totally new conclusions. The basis for this is a free-electron laser – the subject of Sara Thorin’s doctoral thesis – that could be delivered by a developed and modified LINAC.

“The facility is well prepared both in terms of technology and expertise. MAX IV is likely to be my dream workplace for a good while yet.”

Text: Arne Berge

Photo: Kennet Ruona

Facts

-

About MAX IV and ESS

-

Materials research at Lund University

-

Here are some of the Materials research areas that cooperate with industry:

Industriell Produktion (in Swedish)

ProMatEn

Solid Mechanics and 4D Imaging Lab

Building & Environmental Technology and lab, especially

– Water Resources Engineering with Water Portal and WIN

Solid State Physics, NanoLund with Lund Nano Lab, ProNano initiativet (in Swedish) and ProPlacement

Polymer & Materials Chemistry and nCHREM

Industrial design and Product Development

Atomic Physics with Lund Laser Centre

Nuclear Physics with Lund Ion Beam Analysis Facility