Nature inspires researchers to develop green processes and products

Think of the aroma of decaying leaves in a forest in the autumn. Much of the scent comes from bacteria and fungi in the soil which are breaking down the plant debris.

Nature’s decomposition processes provide researchers with new ideas on how fuel, plastics, chemicals and ingredients for household products, to mention but a few examples, can be produced from the waste products of agriculture and forestry – a crucial piece of the puzzle in the transition towards a fossil-free society.

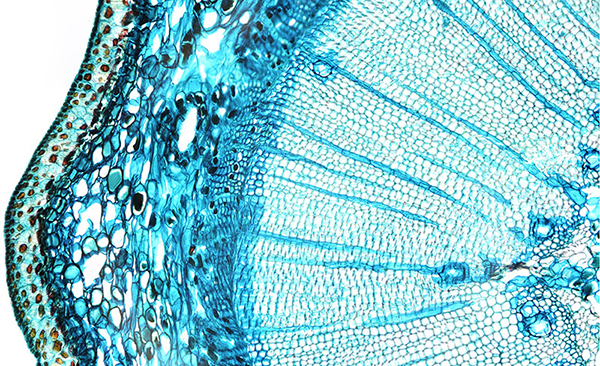

Today, less than one per cent of these fibres are used to make new materials – most of them are incinerated. Using nature’s own tools – enzymes, bacteria, yeasts – the plant fibres can be broken down into smaller components and then used as raw materials for the production of everything from cleaning products to functional foods and new materials.

“Previously, it was mostly the part of the plant fibres called cellulose that was used as a raw material, mainly in the production of paper. Meanwhile over half the plants’ fibre pulp consists of hemicellulose and lignin. There is great potential here”, says Henrik Stålbrand, professor of biochemistry at Lund University.

DEVELOPING GREEN INDUSTRIAL BIOTECHNOLOGY requires an understanding of how enzymes and microorganisms function and can be controlled. Research in this field is intensive. Henrik Stålbrand is in charge of a major project focusing on coniferous hemicellulose, which makes up a large proportion of the raw material from forestry but is not currently used.

In the project, Henrik Stålbrand and his colleagues are studying how the most common type of hemicellulose in coniferous trees, galactoglucomannan (GGM) can be refined and used. They are developing biocatalytical methods – i.e. techniques in which they use enzymes to change the structure of the hemicellulose, thereby conferring new functions on the material.

“By extracting the GGM released from the pulp processing and developing sustainable biocatalytic technology to change the function of GGM, we can confer new, usable properties on it”, says Henrik Stålbrand.

Text: Nina Nordh

Facts

-

The project Biocatalysis for new products based on hemicellulose

-

The project, entitled Biocatalysis for new products based on hemicellulose, includes researchers Henrik Stålbrand (project manager), Tommy Nylander, Patric Jannasch and Ola Wallberg from the Faculty of Science and the Faculty of Engineering at Lund University. The project requires expertise in enzymology/enzyme technology, biochemical process technology, separation technology, process design, physical chemistry and polymer and materials chemistry. The project also involves cooperation between universities and companies.

-

Research at Lund University on Circular bio-based economy

-

Forskning kring plast för ett hållbart samhälle – MISTRA: (in Swedish)

Samarbeten för nya biobaserade produkter och processer – LUBIRC: (in Swedish)