Using bioplastics for 3D printing – three questions for Olaf Diegel

Professor of Product Development at the Lund University Faculty of Engineering (LTH)

What is the challenge, and advantage, of 3D printing with new biopolymers, that is, plastic material from renewable sources?

“When printing in 3D, every material prints differently in terms of how the material shrinks when solidifying, how it flows, how it bonds with the layers beneath, etc. For this reason, every polymer intended to be used for 3D printing needs to be specially tailored and tested for 3D printing. And biopolymers are, of course, better from a sustainability point of view, so they will offer great advantages for product developers who want to create products that have a reduced negative impact on the environment.”

“As the world market for 3D printing is rapidly increasing, a whole new market for 3D printing has emerged. So, potentially, with the biopolymers developed in the STEPS programme, Sweden could become a supplier of 3D printing materials to the rest of the world.”

Olof Diegel

What is the advantage of using 3D printing when designing a product that is more recyclable?

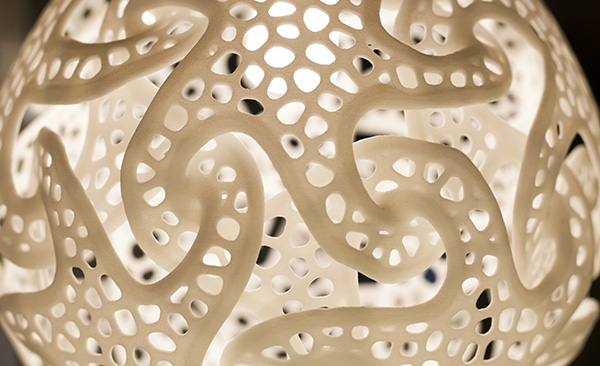

“Any product that is to be recycled can benefit from 3D printing with biopolymers on two main fronts. Firstly, the material itself is tailored to biodegrade in a controlled way. Secondly, 3D printing allows you to create complex hollow lattice structures (rather than solid masses), which also helps speed up the biodegradability of the product.”

Your aim is also to design products so that they become lighter and require less plastic material – what is the benefit of that?

“In terms of the environmental impact, any product that uses less plastic material would be a great improvement. If your mobile phone, for example, required 50g of plastic instead of 100g, but had the same physical size and functionality, that would have obvious benefits. And any products that, for example, need to be shipped from point A to point B benefit from being lighter, and again would help reduce the environmental footprint of the product.”

Text: Pia Romare

Photo 1: Gunnar Menander

Photo 2: Kennet Ruona